How to prepare for EPR

Learn more about the steps you can take to prepare for EPR regulations.

Extended producer responsibility (EPR) is an actively evolving regulatory tool that requires producers, importers, and distributors to be responsible for the end-of-life management of their products. One prevalent focus for EPR regulations around the world is on packaging. EPR programmes for packaging are currently being rolled out across the United States, and laws are also evolving in Canada and Europe.

If you sell a product that is in a package – as most are – then you may be affected by EPR legislation, which often defines producers broadly as the entity that places the packaging in the market, including both brands and importers.

EPR regulations are often implemented into national or sub-national legislation, and requirements often vary greatly between countries, jurisdictions, and schemes. Find out more about the current state of packaging EPR across North America and Europe, and what you need to know about upcoming changes.

EPR Laws Are Live — Are You Ready?

Extended Producer Responsibility (EPR) laws are rolling out across the world.

- Up to $25,000/day in fines

- Real reputational risk from public non-compliance lists

- Loss of market access to regulated states

Don’t risk being caught unprepared.

Packaging EPR in the United States

In the United States, California, Colorado, Maine, Minnesota, Washington, Maryland, and Oregon are all working to implement packaging EPR laws. Twelve states have also introduced or are in the process of introducing legislation.

States

- California

- Colorado

- Maine

- Oregon

- Minnesota

- Washington

- Maryland

California

California is on track to have EPR implemented by 2027. Recent developments include:

- CalRecycle recently completed its covered materials list defining packaging that is considered recyclable in California.

- The draft regulations have outlined specific requirements for the use of the “chasing arrows” symbol which has been labeled as misleading by SB 343.

- Circular Action Alliance (CAA) was named as the first Producer Responsibility Organisation (PRO) for California.

This year, companies will need to submit reporting to the CAA to create the baseline that fees will be based on. The reporting period will be open from September 15, 2025 to November 15, 2025, and companies must report their volumes using 2023 sales data.

California has also built targets into their regulations for increasing the recyclability of plastic packaging. On behalf of producers, the PRO must ensure that by January 1, 2032:

- 100% of packaging in California is recyclable or compostable;

- 25% of plastic packaging is source reduced;

- 65% of all single-use plastic packaging is recycled.

Colorado

Colorado, notorious for its below-average recycling rate, is making progress on implementing its Producer Responsibility Programme for Recycling. The Colorado Department of Public Health and Environment has named CAA as the state’s designated PRO and the first report was due on July 31, 2025. CAA is responsible for completing the state’s needs assessment and is the administrator of the funding mechanism.

Colorado’s programme is set to go into effect on January 1, 2026. Next up in Colorado will be receiving finalised rates for invoicing and information on eco-modulation.

Maine

Maine was the first state to pass an EPR bill for packaging in 2021. The programme has been in a rulemaking and implementation phase since its passage, with the Maine Department of Environmental Protection (DEP) working to establish the operational details.

In a significant step forward, the Maine Board of Environmental Protection officially adopted the programme rules in December 2024. A key upcoming milestone is the selection of a Stewardship Organisation (SO) to administer the programme, with the DEP planning to issue a request for proposals in the fall of 2025 and contract with the SO in the spring of 2026.

The most recent timeline indicates that companies will need to start reporting data on the total tons of packaging they introduced into Maine during the 2025 calendar year in 2026.

Oregon

Oregon’s Plastic Pollution and Recycling Modernisation Act, passed in 2021, is a comprehensive EPR law that shifts the financial and operational burden of managing packaging, paper, and food serviceware from local governments to the producers of these materials.

The law officially began its implementation phase on July 1, 2025, with many of the initial improvements happening behind the scenes, such as upgrading recycling facilities and expanding recycling access to more communities. Producers were required to register with a state-approved PRO, with the CAA being the only one currently approved.

The initial deadline for producers to register and report 2024 supply data was March 31, 2025, though a grace period was offered through April 30, 2025. Following the data reporting, producers are now being invoiced and began making payments to the PRO starting on July 1, 2025. These payments will fund the modernised recycling system and reimburse local governments.

Oregon has also issued guidance on eco-modulation and will be rewarding companies that reduce environmental impacts through packaging redesign and disclosure informed by Life Cycle Assessments (LCAs), powerful tools that evaluate the environmental impacts of a product or package across its entire life.

There are three ecomodulation bonuses available to producers:

- Bonus A: Up to $20,000 in base fees as an invoice credit per Product SKU (or for a batch of product SKUs that use the same LCA report) for submitting a third-party reviewed LCA of packaging, for a maximum of 10 SKUs, for a possible invoice credit of up to $200,000

- Bonus B: Up to $50,000 per SKU for demonstrating impact reductions from packaging improvements made since December 2024.

- Bonus C: Incentives for switching from single-use to reusable or refillable packaging systems.

While all three bonuses offer substantial savings, Bonus A is the most immediate and accessible opportunity. Bonus A allows producers to submit up to 10 LCAs, either for individual SKUs or batches of similar SKUs, and receive up to $200,000 in EPR fee reductions for the following year. The bonus is calculated as 10% of the base EPR fees for the materials in each SKU, capped at $20,000 per SKU. While the initial submission deadline has passed, companies should prepare LCAs now to be eligible for Bonus A savings in 2027, positioning themselves ahead of the curve and maximizing future cost reductions.

Importantly, if a company selects 10 SKUs with similar packaging, they may only need to conduct one LCA to cover all of them. LCAs for packaging, especially when formats and materials are consistent, are typically more straightforward and less complex than product LCAs. As a result, the cost of conducting the assessment is only a fraction of the potential $200,000 in EPR fee reductions. When applied, the savings from Bonus A can fully fund the assessment, making it a net positive investment. It also positions companies to qualify for Bonus B and Bonus C in future reporting cycles. This is especially advantageous for companies with high packaging volumes, where EPR fees are substantial.

Anthesis offers a turnkey solution to help you with your process to meet Oregon DEQ’s Life Cycle Evaluation guidance and ISO 14044 standards by following the required methodology and documentation practices. We also offer to coordinate the independent third-party review, streamlining the process and reducing the administrative burden for your team.

Our North America-based team brings together:

- Top-tier LCA practitioners with expertise in plastic packaging

- Packaging engineers skilled in resin analysis and leakage quantification

- Waste experts who understand end-of-life pathways and waste metrics

- Green chemistry specialists for toxicity and health impact assessments

This multidisciplinary approach equips us to address the specific and technically demanding elements of Bonus A, such as plastic and methane leakage calculations, hazardous substance disclosure, and human health impact statements, with precision and rigor.

It’s important to note that while some of the data collected for EPR fee calculations, such as packaging weight and recycled content, can be reused for the LCA, the assessment requires much more detailed and comprehensive information. LCAs dive deeper into the full environmental profile of packaging. This includes data on packaging formats, manufacturing processes, transportation distances, energy use, end-of-life scenarios, and more.

Minnesota

Minnesota’s Packaging Waste and Cost Reduction Act, passed in 2024, establishes a comprehensive EPR programme that requires producers of packaging and paper products to be financially responsible for the recycling system. This shifts the burden from taxpayers to the companies that create the waste.

The law officially began its implementation phase with a significant deadline on July 1, 2025, by which all non-exempt producers were required to register with a state-approved PRO, with CAA currently holding that role. While producers have started to register and data collection is underway, the main funding and operational responsibilities are being phased in.

The first stewardship plan from the PRO is due in October 2028, with full programme implementation, including producers covering at least 90% of recycling and composting costs, by January 2032. The CAA is working to align Minnesota’s guidance with California’s, and the programmes are expected to require similar reporting.

Maryland

Maryland’s EPR law for packaging and paper products, Senate Bill 901, was signed into law in May 2025, making it the sixth state to enact such legislation. This law requires producers to fund and manage a portion of the state’s recycling system through a PRO. While Maryland has already selected CAA as its PRO, the programme is in an early implementation phase.

Producers will need to register with the Maryland Department of the Environment by July 1, 2026. The most significant financial obligations and reporting milestones are still a few years away, with the first producer responsibility plan due on or before July 1, 2028. This plan will establish the eco-modulated fees that producers will pay and will set the initial target for reimbursing municipalities, with a goal of covering at least 90% of eligible costs by 2030.

Washington

Washington’s Recycling Reform Act, signed into law in May 2025, establishes an EPR programme for residential packaging and paper products. This legislation makes producers accountable for the end-of-life management of their products by requiring them to join and fund a PRO.

The implementation of the law is a multi-year process with various deadlines. Producers are required to appoint a PRO by January 1, 2026, and must register with the PRO by July 1, 2026. After that, a PRO must submit a draft programme plan to the Department of Ecology by October 1, 2028. Full programme implementation, including producers reimbursing at least 90% of the recycling system costs, is scheduled to begin in 2032, providing a multi-year runway for a phased transition.

Packaging EPR in Canada

Like the United States, Canada allows each province to implement its own waste management and recycling programmes. The provinces of British Columbia, Saskatchewan, Manitoba, Ontario, New Brunswick, Alberta, Quebec, Nova Scotia and the Yukon have legislation and regulations that provide for either full or partial funding of the packaging recycling system by obligated businesses.

In 2019, the Canadian Council of Environment Ministers published its Canada-wide Action Plan on Zero Plastic Waste, a key component of which called for a transition to full EPR programmes in all provinces. While a guidance document was prepared to help achieve harmonisation, the implementation and timelines continue to vary significantly by province. Prince Edward Island and Newfoundland and Labrador are also in the process of developing or exploring their own EPR frameworks.

Provinces and territories

- Ontario

- Quebec

- British Colombia

- Manitoba

- Saskatchewan

- Alberta

- New Brunswick

- Nova Scotia

- Yukon

- Prince Edward Island, Newfoundland & Labrador

Ontario

Ontario’s transition to a full EPR programme for packaging is nearing completion. Phased in community by community since 2023, the programme is on track for full implementation by the end of 2025. This transition shifts financial and operational responsibility from Stewardship Ontario to producers, who are now obligated to cover 100% of the costs for managing “Blue Box materials.” Producers must work with a PRO to fulfill their obligations, with the Resource Productivity & Recovery Authority (RPRA) overseeing the programme.

Quebec

Quebec is transitioning to a modernised, producer-funded system for selective collection (recycling) and deposit-return programmes. The transition to a fully producer-funded system is expected to be complete by the end of 2025. The non-profit body Éco Entreprises Québec (EEQ) has been designated as the PRO to manage the selective collection system, while the Quebec Association for the Recovery of Beverage Containers manages the deposit-return system. The new framework gives PROs responsibility for the collection, sorting, and baling of recyclable materials.

British Columbia

British Columbia’s Packaging and Paper Product Extended Producer Responsibility Plan, in place since 2014, was the first full EPR programme in Canada. The programme, managed by RecycleBC, has a long-standing track record of success. It defines packaging broadly to include primary, secondary, tertiary, and service packaging, and accepts a wide assortment of materials. RecycleBC has consistently met or exceeded its recovery rate targets, even for challenging materials like plastic packaging.

Manitoba

Multi-Material Stewardship Manitoba (MMSM) is in the process of transitioning its programme from a cost-sharing model to a full industry-funded recycling programme. Under the previous system, industry funded 80% of costs; the transition will bring this to 100%. MMSM will serve as the sole PRO for the province, with the responsibility of setting a harmonised list of acceptable materials for recycling across Manitoba.

Saskatchewan

Saskatchewan’s transition to full EPR is underway and is very similar to Manitoba’s approach. The programme, known as SK Recycles, is being implemented in phases, with a target completion date by the end of 2027. Multiple Material Stewardship Western (MMSW) has been designated as the PRO for the province. Like British Columbia and Manitoba, Saskatchewan is working closely with the not-for-profit organisation Circular Materials to implement its programme.

Alberta

Alberta’s new EPR framework for packaging, paper, and single-use products began its transition in 2025. This shift will make producers 100% responsible for operating and funding the recycling system. The transition is being phased in, with communities that had existing collection services as of November 2022 transitioning on April 1, 2025, while others will transition later in 2026. Circular Materials has been approved as the PRO for the province.

New Brunswick

New Brunswick is in the midst of a transition to an EPR programme for packaging and paper products, with Circular Materials designated as the PRO. A key recent milestone was the expansion of the programme, which took effect on May 1, 2025, to include multi-family residences and schools. This is a multi-phase implementation, with full system integration continuing over the next several years.

Nova Scotia

Nova Scotia’s EPR programme, established by law in 2021, is moving quickly toward full implementation by the end of 2025. Producers were required to register with Divert NS by January 1, 2024, and have already submitted their initial reports. The province is on track to have producers fully responsible for the delivery of curbside recycling by December 1, 2025, though details on acceptable materials and the full list of PROs are still being finalised.

Yukon

The Yukon is a recent addition to the Canadian provinces and territories with a dedicated EPR programme for packaging and paper products. While the regulations officially came into effect in early 2024, the programme’s operational launch is scheduled for November 1, 2025. This means that, starting on that date, producers will be financially and operationally responsible for managing the end-of-life of their packaging and paper products. Circular Materials has been approved as the Producer PRO to manage the programme.

The regulation includes specific exemptions for small producers, such as those with less than $1 million in gross revenue in the Yukon or those who supply less than one tonne of designated materials annually. The implementation of this programme is a key part of the Yukon’s “Our Clean Future” strategy, aiming to reduce waste management costs for municipalities and increase recycling rates.

Prince Edward Island and Newfoundland and Labrador

Prince Edward Island has introduced legislation to move its deposit-return system toward an EPR framework, but the timeline for implementation is not yet known. Newfoundland and Labrador is also in the early stages of consultation to develop an EPR plan for packaging and paper products.

Canada Plastics Registry

The Canadian federal government has implemented a national Federal Plastics Registry (FPR) to collect comprehensive, standardised data on plastics throughout their lifecycle in Canada. Established under the Canadian Environmental Protection Act (CEPA), the registry is a mandatory reporting initiative that aims to provide a clear, nationwide picture of plastic use, from production to end-of-life management.

Unlike the provincial EPR programmes, which are primarily focused on funding recycling systems, the registry is a data-gathering tool designed to support federal policy development and track progress toward Canada’s goal of zero plastic waste by 2030. The reporting requirements are being phased in, with the first deadline having recently passed on September 29, 2025, for data from the 2024 calendar year.

This initial phase requires producers of plastic packaging, electronic and electrical equipment, and single-use plastics destined for the residential waste stream to report on the quantity and type of plastics they place on the market. Future phases will expand the scope to include additional sectors, more detailed end-of-life data, and reporting by resin manufacturers, importers, and waste generators. The data required for the FPR is similar to what is needed for Packaging EPR reporting requirements.

European EPR: the Packaging and Packaging Waste Directive (PPWR)

Packaging EPR in the Europe

Under the Packaging and Packaging Waste Directive 94/62/EC of 1994, the member states of the European Union have been working to prevent the production of packaging waste through reuse, recycling, and other means. However, the directive did not harmonise the approaches and created a suboptimal approach for the economic alliance.

With the European Green Deal and its subsequent Circular Economy Action Plan came the need to revisit the directive and create a standardised approach through a regulation. A draft Packaging and Packaging Waste Regulation (PPWR) was published in 2022 that outlined requirements for the entire packaging life cycle and for extended producer responsibility. With a harmonised approach, Member States would not be allowed to prohibit, restrict, or impede the placing on the market of packaging that complies with the directive.

Fast forward to today and the regulation was adopted in Oct 2023 by European Parliament. Its scope covers all packaging and all packaging waste, regardless of origin.

The proposed definition of recyclable packaging includes packaging that is designed for material recycling and then collected, sorted, and recycled at scale. The scale criterion will not take effect until 2035 to allow for an infrastructure build.

A major point of contention, especially in the recycling industry, is allowing bio-based plastics to be counted as a contributor to recycled content targets. Recyclers argue that bio-based should be separate from recycled as grouping them could diminish the importance of recycling as a means of creating circular materials for packaging.

For plastic recyclers, the question of whether chemical recycling will fit into the definition of “recycling”, or if chemically recycled plastics will count as “recycled content”, is still unsettled.

The regulation also responds to a demand for clear labelling to ensure that consumers are well informed about the packaging materials and waste management instructions. The objective to have one harmonised label has been reshaped to allow for labelling systems that may already be in place.

UK EPR guidance

The United Kingdom

In July 2023, the UK Government and Defra published further updates on the roll out of EPR. There has been another delay in the introduction of EPR in the UK as Defra continues to take a ‘phased manner’ approach to implementation of new packaging requirements.

Producer financing has now been deferred a year from Oct 2024 to 2025 – at this time we understand this means that sales made in 2024 will be paid for in 2025 under the new reporting system.

Producer data reporting does not appear to have changed, and we expect the current formats and deadlines (1st Oct 2023) to remain in place.

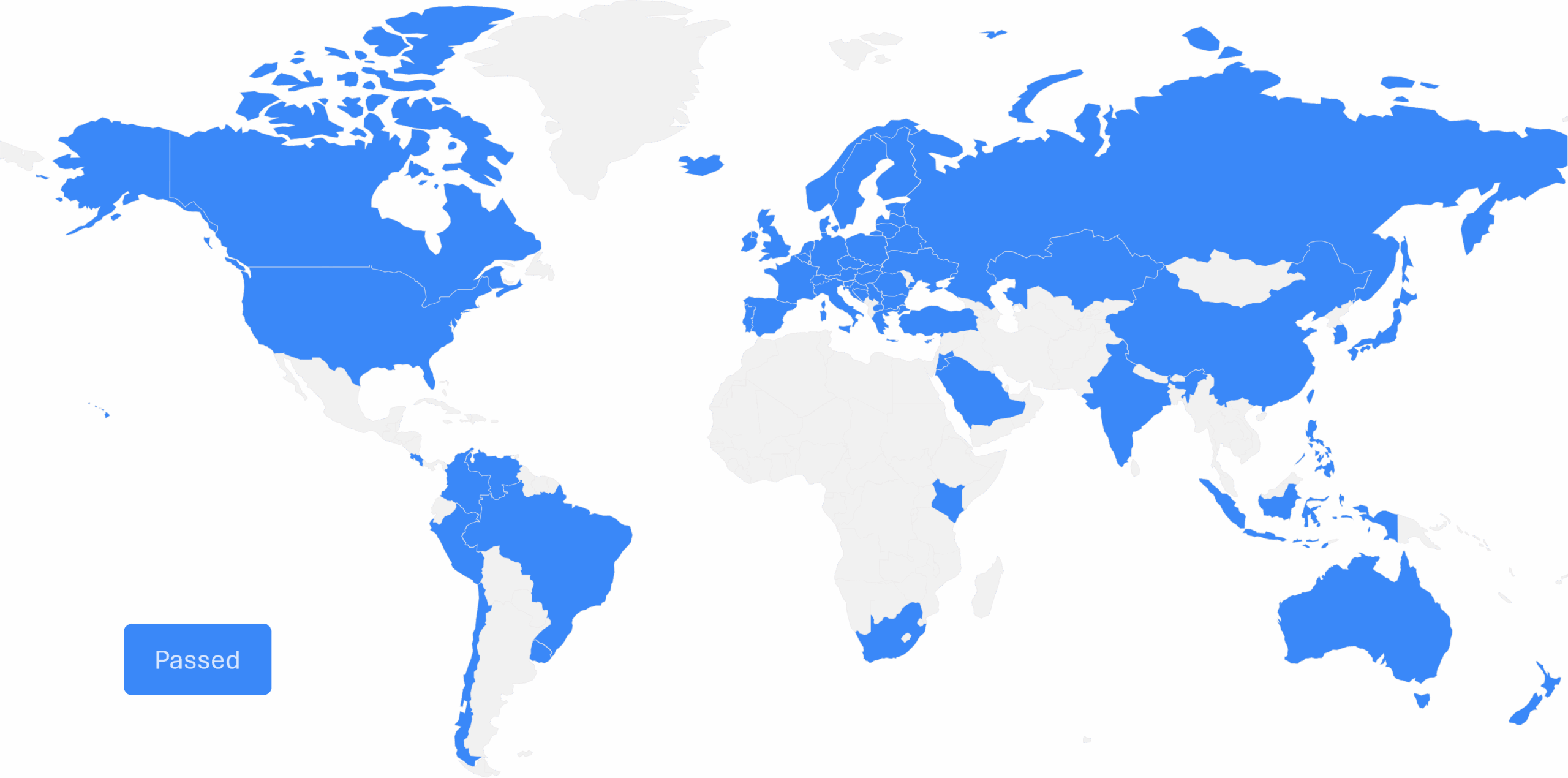

Packaging EPR Globally

Approximately 63 countries globally have some form of Extended Producer Responsibility (EPR) system for packaging, covering a range of structures from mandatory, fully-funded schemes to voluntary or pilot programmes.

Countries outside of the EU, UK, US, and Canada are increasingly adopting EPR regulations for packaging to combat rising waste and plastic pollution.

Regions

- Asia

- Latin America

- Rest of World

Middle East

In 2024, the UAE launched its first Extended Producer Responsibility (EPR) pilot to address electronic equipment, battery, and packaging waste. The six-month pilot, announced by the Ministry of Climate Change and Environment, is being implemented in Abu Dhabi and Dubai as part of the UAE’s Integrated Waste Management Agenda 2023–2026.

The pilot introduces shared producer responsibility through a central Producer Responsibility Organisation (PRO) and involves voluntary participation from private-sector companies across retail, manufacturing, and waste management. While still at an early stage, the pilot signals a clear policy direction toward producer accountability and circular economy principles in the region.

Asia

In Asia, countries like India and the Philippines have recently introduced mandatory EPR laws. India’s framework, established in 2022, requires producers to meet specific targets for collection and recycling, with the goal of phasing in full implementation by 2028. The Philippines’ EPR Act of 2022 mandates that large companies progressively recover a certain percentage of their plastic packaging, reaching an 80% recovery target by 2028.

Other Asian nations, including South Korea and Japan, have had EPR schemes for many years, with South Korea’s programme often cited as one of the most comprehensive, covering a wide range of materials and having achieved high recycling rates. China is in the process of developing a comprehensive EPR framework for packaging, but it does not yet have a single, national, and fully operational system like those in Europe or North America.

Latin America

Latin America is also seeing a surge in EPR legislation, though implementation varies. Chile has a well-established EPR law from 2016 that mandates producers take responsibility for several priority products, including packaging, and has a functioning system of PROs. Colombia has had a legal framework for EPR since 2018, requiring producers to submit and report on their waste management plans.

Brazil has a unique approach, focusing on a “reverse logistics” system where producers must prove they have taken back and recycled a certain amount of packaging through the purchase of recycling certificates. Other countries in the region, like Mexico and Peru, have national frameworks or are in the process of developing them, with specific regulations often differing at the state or regional level.

Rest of World

In other parts of the world, South Africa is a leader in implementing EPR. Mandatory EPR regulations for packaging and paper products were put in place in May 2021, and they require all producers to join an approved EPR scheme or establish their own. This move shifted the country’s previous voluntary system to a binding, mandatory framework.

Meanwhile, Australia and New Zealand are also moving toward stronger, mandatory schemes. While Australia’s system has historically been co-regulatory, with a mix of voluntary and regulated targets, new developments are pushing for more rigorous, mandatory compliance with an emphasis on “eco-modulated fees” that reward more sustainable packaging. New Zealand has mandated EPR for plastic packaging and is working to phase out difficult-to-recycle plastics.

How to prepare for EPR

Packaging EPR is designed to hold producers accountable for the end-of-life management of the packaging they introduce to the market, while promoting eco-design practices. Under this framework, fees are typically calculated based on the weight and, in some cases, the format of the packaging materials. Knowing the origin of materials is also key, as it can qualify producers for eco-modulated fee reductions.

Preparing for EPR requires extensive data collection and analysis. High-quality data not only helps reduce current fees but also informs strategies to minimise costs in future reporting periods.

Learn more about the steps you can take to prepare for EPR regulations here.