Table of Contents

- Compliance Requirements

- Steps to Prepare

- Why Start Now?

- Potential Challenges

- How Anthesis Can Help

- Contact Us

Share this article

The EU Batteries Regulation (Regulation (EU) 2023/1542, EUBR) came into force in August 2023 as part of the European Green Deal and Circular Economy Action Plan. It applies to economic operators (manufacturers, importers, distributors) placing portable, automotive, EV, and industrial batteries on the EU market with turnover above €40 million, unless part of a group that exceeds that threshold.

The due diligence guidelines are a cornerstone of this framework, addressing human rights, environmental, and social risks in the batteries supply chain. The aim is to prevent human rights abuses, environmental degradation, and conflict financing in the sourcing of critical raw materials such as lithium, cobalt, nickel, and natural graphite.

While enforcement of the due diligence obligations has been delayed to August 2027, companies should not wait to act. Preparing well in advance can help companies avoid added complexity and challenges when obligations do come into effect, and can lead to added business value in the lead up to enforcement.

Compliance requirements

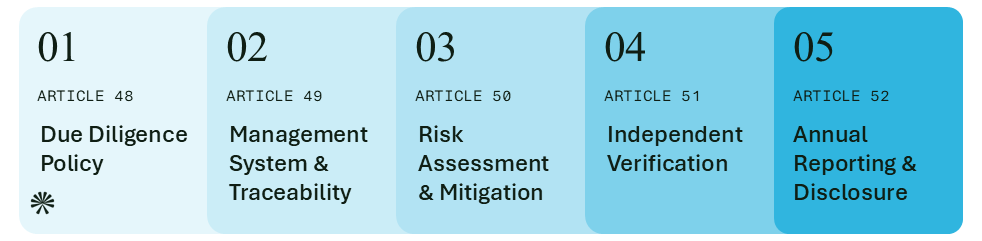

Chapter 7 of the EUBR (‘Obligations of economic operators as regards battery due diligence policies’) comprises seven articles and sets out five key requirement areas:

- Due Diligence Policy (Article 48): Create and maintain a documented policy for battery supply chain due diligence, verified by an independent auditor.

- Management System & Traceability (Article 49): Implement internal systems and traceability mechanisms to monitor supply chains and address grievances.

- Risk Assessment & Mitigation (Article 50): Identify human rights and environmental risks in battery material supply chains and develop strategies to mitigate them.

- Independent Verification (Article 51): Have all due diligence processes independently reviewed and validated by a notified third party.

- Annual Reporting & Disclosure (Article 52): Publish an annual report detailing due diligence actions, findings, and corrective measures.

Beyond the due diligence rules, the EUBR imposes a phased package of other sustainability measures:

- Carbon footprint declarations (phased from 2025-2030)

- Minimum recycled content for cobalt, lithium, nickel, and lead (mandatory from August 2031)

- Battery passport (mandatory from 2027)

- Collection and recycling targets (63% by 2027, 73% by 2030)

- Removability and replaceability (portable batteries by 2027)

Steps companies can take to prepare

To prepare for compliance with EUBR due diligence requirements, companies should consider the following key steps:

- Clarify governance and compliance responsibilities: Gain a solid understanding of the EUBR legal requirements and establish an internal governance structure to ensure compliance obligations can be effectively managed.

- Map the supply chain: Build visibility into the battery supply chain, with a focus on identifying upstream suppliers and high-risk areas that require closer scrutiny.

- Communicate and engage with suppliers: Begin collecting traceability information by working closely with suppliers. Consider systems to support this outreach, data collection, and reporting such as Anthesis Compliance Suite (ACS). Strengthen engagement by presenting a clear business case for why providing traceability data benefits both sides.

- Conduct a rigorous risk and impact assessment: Conduct a thorough risk assessment to identify the most significant human rights and environmental risks and associated impacts, as well as priority areas for action across the battery supply chain.

- Implement risk mitigation strategies: Begin acting on risk assessment findings by deploying appropriate mitigation measures. These may include supplier audits, self-assessment questionnaires for Tier 1 suppliers, in-depth human rights impact assessments (HRIAs), and partnerships with civil society organisations.

- Develop a due diligence policy: Formalise your approach in a due diligence policy, which will not only meet EUBR requirements but can also serve as a foundation for compliance with broader regulatory frameworks such as the CSDDD.

Why start preparing now?

Long lead times

Establishing due diligence systems is a complex process that requires significant time and resources. By August 2027, these systems must be independently verified, which means companies should begin preparing now to avoid a last-minute scramble.

Clear expectations despite limited guidance

While the European Commission has not yet published detailed guidelines, foundational frameworks – such as the OECD Guidelines for Multinational Enterprises and the UN Guiding Principles on Business and Human Rights (UNGPs) – have long defined what constitutes best practice in due diligence. The regulatory text may leave some room for interpretation, but the core expectations are unlikely to change.

Business value beyond compliance

The risk assessment required under the EUBR is not just a regulatory burden. It can serve as a valuable management tool to uncover risks that could affect business operations, as well as impacts on people and the environment. Starting early helps companies realise these benefits, regardless of any regulatory delays or uncertainties.

A step toward broader compliance

For many companies, batteries represent only one of many categories of procured goods. Strengthening due diligence processes in this area now can create a solid foundation for complying with upcoming regulations such as the CSDDD, which will require a more comprehensive supply chain due diligence approach.

Integration with other EUBR sustainability requirements

The EUBR due diligence obligations link closely with other compliance requirements – such as carbon-footprint declarations, recycled-content reporting and the digital battery passport. These rely on consistent product and supplier data structures. Starting now allows firms to design data systems that serve multiple compliance purposes instead of patchwork fixes later.

Complexities companies may encounter

- Transparency varies widely across minerals: Cobalt supply chains are better understood than lithium, nickel, or graphite, while mining operations remain particularly opaque.

- Fragmented data ownership: Relevant data may sit with different teams across the organisation, slowing analysis. Clear data governance and collaboration are essential.

- Complex value chain mapping: Traceability requires significant effort, supplier trust, and data cleaning as upstream information is often incomplete or inconsistent.

- Extensive scope of risk issues: The EUBR covers a wide range of human rights and environmental risk issues. Assessing impacts associated with these risk issues across minerals and value chain stages is resource-intensive and ideally requires stakeholder consultations. Desk-based research and third-party datasets can help, but they often only indicate the likelihood of adverse impacts – not their severity.

- Supplier engagement to address impacts: Identifying risks isn’t enough — companies must work with suppliers on corrective actions, training, and monitoring.

- Partnerships beyond Tier 1: Real visibility into smelters, refiners, and mines usually requires partnerships with NGOs and local stakeholders, especially to address sensitive issues like child labour in ASM.

How Anthesis can help

While the EUBR introduces new regulatory requirements, the principles of human rights and environmental due diligence are long established. For over a decade, we have supported leading companies on their due diligence journeys, applying a proven suite of tools and methodologies:

- Digital tools: Our suite of digital tools, such as Compliance Suite, is uniquely positioned to help companies trace their battery supply chains and collect supplier data to support compliance needs.

- Proven methodology for value chain mapping and risk / impact assessment: Our tried-and-tested methodology draws on extensive experience conducting Double Materiality Assessments (DMAs), in-depth, on-the-ground Human Rights Impact Assessments (HRIAs) and Supply Chain Risk Assessments.

- Actionable risk management frameworks: We design and implement comprehensive Risk Management Frameworks to provide clear, actionable steps for addressing identified risks. Our approach ensures that due diligence processes are aligned with regulatory due diligence requirements, proportionate to the severity of impacts, and embedded into day-to-day operations.

- Policy development with practical implementation: While many organisations offer support in developing policies and supplier codes of conduct, ensuring that a policy is practical and implementable requires deep knowledge of organisational processes and hands-on implementation experience. We bring this expertise to all our projects.

- Supplier engagement: Collecting supplier data to support compliance requires close collaboration. Sending data requests without clearly communicating the benefits of accurate reporting and effective risk management often results in low response rates. We have extensive experience in supplier engagement – building capacity, setting goals, developing action plans and conducting ongoing monitoring to evaluate and track progress.

Learn more about Compliance Suite

Cloud-Based Compliance Management Software Solution for Effortless Material Compliance and Conflict Minerals Management

We are the world’s leading purpose driven, digitally enabled, science-based activator. And always welcome inquiries and partnerships to drive positive change together.