Contents

- Preparing for EPR

- Packaging baselines

- Applying the fees

- Preparing for the future

- How Anthesis can support

Share this article

Summary

- EPR compliance is a two-part process.

- A good packaging baseline provides the total packaging materials placed in an individual market. It is a data intensive task that can be complicated when outsourced units are involved.

- Accurate EPR fees require a detailed understanding of the PRO fee structure. These vary in attribute and amount, even in the same market.

- When considering packaging EPR compliance, is this something that you want to teach yourself or learn from a trusted teacher?

Organisations around the world are grappling with the evolving landscape of Extended Producer Responsibility (EPR).

The intent of EPR is clear: to ensure producers take responsibility for managing the end of life of packaging placed on the market, while encouraging eco-design principles that reduce environmental impact.

EPR compliance

Most EPR laws require producers to join a Producer Responsibility Organization (PRO), report packaging data (type, volume, recyclability), and pay fees based on packaging quantity and sustainability.

However, EPR is about more than just compliance – it’s a business risk to manage and an opportunity to embrace. The transition from simply meeting EPR obligations to leveraging them as a driver of sustainability and business value is critical. By approaching compliance strategically, companies can not only avoid penalties but also unlock cost savings, design efficiencies, and deliver stronger circularity outcomes.

In fact, engaging deeply with EPR obligations can deliver:

- Cost savings through better data and design decisions

- Eco-modulation fee reductions

- Competitive advantage by embedding sustainability principles into operations

Preparing for EPR

Under packaging EPR legislation, fees are typically assessed based on material weight, packaging format, and in some cases, material source, with eco-modulation mechanisms rewarding the use of recycled and sustainable inputs.

Eco-modulation adjusts producer fees in Extended Producer Responsibility (EPR) programs based on how environmentally friendly and recyclable their products are—rewarding sustainable design and penalizing harmful materials.

Preparing for EPR involves a lot of data gathering and analysis. Better data can lead to lower fees and provide insights into strategies for further reductions in future years.

However, EPR can often be overwhelming, especially within geographies like the United States where the landscape is evolving quickly. Common pain points are being felt around:

- packaging data gaps and inconsistent packaging information

- uncertainty about what’s in scope for each jurisdiction

- tight (and sometimes surprising) deadlines

- cross-functional coordination challenges

There’s also the danger of financial penalty and reputational risk for non-compliance.

In order to build out a business strategy for EPR, companies need to access their packaging portfolio, engage with suppliers, and build the internal systems necessary to support ongoing compliance.

EPR Laws Are Live — Are You Ready?

Extended Producer Responsibility (EPR) laws are rolling out across the world.

- Up to $25,000/day in fines

- Real reputational risk from public non-compliance lists

- Loss of market access to regulated states

Don’t risk being caught unprepared.

Step 1: data collection & packaging baselines

Accurate data is the foundation of EPR compliance. Many organizations struggle with errors, inconsistencies, and missing information. Establishing a robust data management system with validation processes, standardized entry forms, and regular audits is essential.

A clear map of your products’ route to market and flow of packaging through the business is essential to knowing which EPR requirements apply to your business, and what data you will need to collect on product packaging. This map will also help you identify your top suppliers – in other words, your key data sources.

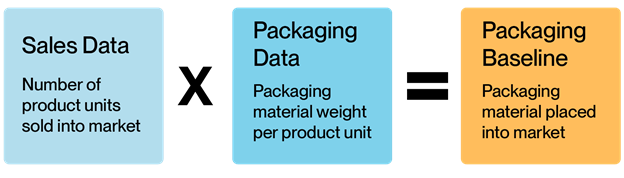

With this understanding, you can conduct a packaging baseline, one of the first steps to EPR compliance. When completed, a packaging baseline provides a link between sales into a market and the packaging materials that were delivered into that market. While most organizations can provide item-based sales data, the challenge lies in mapping packaging materials.

Key questions to answer include:

- What are the primary, secondary, and tertiary packaging items used for each selling unit?

- What materials are used in each packaging item?

- Are there any problematic materials or items?

- Do the materials contain any recycled content?

- Were the materials sustainably sourced?

Insourcing & vendor assessments

For selling units that are insourced, a bill of materials and a survey of packaging suppliers should be able to answer the key questions. When units are outsourced and packaging is included as part of the item, answering the key questions involves a detailed survey of suppliers that can consume valuable hours and distract from more strategic initiatives.

Download our guide to conducting an effective packaging baseline

Anthesis utilises tested processes and compliance systems to streamline the supplier engagement survey process and deliver high participation rates. Proprietary uplift methods are employed to complete the dataset. All steps are well documented to ensure easy validation and replication.

Hotspot analysis

With a packaging baseline in place, it is then possible to conduct hotspot analysis to identify potential gaps in your packaging sustainability, impact assessments to determine a cost estimate of EPR fees, and a readiness assessment to determine your capacity to make necessary changes.

Learn more about the steps you can take to build internal systems for data and compliance, overcoming common data challenges, engaging your supply chain for more comprehensive data, and staying on track with EPR reporting in our recent webinar.

Designing for compliance

Integrating EPR considerations into packaging design reduces future fees and risks. Actions such as lowering material weight, eliminating unnecessary components, and using recycled or sustainably sourced materials not only improve compliance but also contribute to eco-modulation incentives.

EPR webinar

Join Anthesis packaging EPR experts as they address what we’ve learned so far in helping clients to define their methodology, gather their numbers, and submit on-time reports.

Step 2: applying the fees

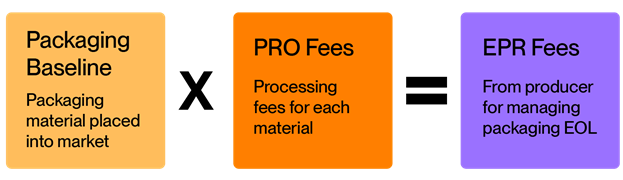

Once the baseline is established, EPR fees must be calculated. These are typically managed by Producer Responsibility Organizations (PROs), which collect fees to fund packaging waste management and recycling initiatives.

Legislation sets requirements for PROs to achieve certain goals (waste reduction, recycling, etc.) but usually does not set fees because the intent is to allow the PRO to efficiently deliver on the goals. This means that understanding the fee for a specific material can be a complicated task, with hurdles including:

- Fee complexity: PROs operate under legislation but often set their own fee structures. This creates variability, even within the same market, and makes accurate calculation challenging.

- Required updates: Because PRO fees change, disclosures must be updated regularly. The formula is simple – packaging baseline × PRO fees = EPR fees – but the underlying data requires ongoing monitoring.

EPR fees are paid on a frequency set by the PRO. Accurate disclosures require an update of the baseline and an update of the PRO fees.

Anthesis handles the EPR reporting requirements for many multi-national corporations. The regulations, reporting requirements and the ways of most of the PROs have been studied and are routinely updated. This way, Anthesis can deliver accurate fee reports for any EPR program.

It is worth noting that the same methodology can be useful in determining the additional tax obligations for UK, Spain, and soon to see in Germany and Italy. With an accurate baseline, strategies can be developed to minimise tax obligations in future years.

Eco-modulation: a key lever

Eco-modulation adjusts EPR fees based on the environmental performance of specific packaging. For example, Oregon rewards companies that demonstrate improvements via Lifecycle Assessments (LCAs). Though time-consuming, LCAs provide precise insights into packaging performance, supporting both fee reductions and broader sustainability goals.

Preparing for the future

As EPR regulations expand, organizations must move beyond compliance to embed resilience and circularity into their packaging systems and operations. Key strategies include:

- Data Quality & Management: Accurate data is the foundation of EPR compliance. Many organizations struggle with errors, inconsistencies, and missing information. Establishing a robust data management system with validation processes, standardized entry forms, and regular audits is essential.

- Forecasting & Planning: Anticipate shifts in fee structures and build them into budgets and product roadmaps.

- Building Compliance Capabilities: Develop strong internal systems or partner with trusted advisors to navigate evolving rules.

- Embedding Sustainability: Align EPR with product development, turning compliance into a driver for innovation, reduced costs, and enhanced brand reputation. Actions such as lowering material weight, eliminating unnecessary components, and using recycled or sustainably sourced materials not only improve compliance but also contribute to eco-modulation incentives.

How Anthesis can help

To successfully navigate the complex and evolving landscape of Packaging EPR, companies can leverage Anthesis to develop a strategic approach. Our product and packaging experts can help reduce a company’s financial burden and compliance risk by first conducting a thorough analysis of their packaging portfolio and Bill of Materials (BOMs) to identify all obligated materials across different jurisdictions.

Our team of packaging engineers ensures accurate data gathering and reporting, which is critical for meeting varied state, provincial, and country requirements and avoiding costly penalties.

Beyond managing EPR compliance, Anthesis can assist in interpreting eco-modulated fees, identifying opportunities to reduce costs by redesigning packaging to be more recyclable, using recycled content, or lightweighting. We also serve as an essential resource for staying up-to-date on new legislation, upcoming deadlines, and adjacent regulations, such as recycled content mandates, single-use plastic bans, and EPR requirements for new categories like Textiles, helping companies implement proactive strategies that not only ensure compliance but also transform EPR from a regulatory burden into a long-term sustainability advantage.

Contact us

Speak with our experts and discover how we can support you in creating impactful, purpose-driven communications for your brand.