Table of Contents

- What are PFAS?

- PPWR Requirements for PFAS

- Future Implications for PFAS

- Next Steps

- How Anthesis Can Help

- Contact Us

Share this article

The EU’s Packaging and Packaging Waste Regulation (PPWR), published in February 2025, introduced an EU-wide restriction on Per- and polyfluoroalkyl substances (PFAS) in food-contact packaging, set to apply from 12 August 2026. The PPWR also addresses substances of concern (SoCs) and recycled content, both of which may have implications for PFAS content in other types of packaging. In this article, we explore the PFAS requirements introduced by the PPWR, and what they mean for your business.

What are PFAS?

PFAS are a large group of chemicals that have been widely used in various industry and consumer applications since the 1950s. PFAS are particularly valued for their water and grease resistance and thermal stability, making them useful in many packaging applications such as fast-food wrappers, pizza boxes, microwave popcorn bags, and takeaway containers. PFAS can also contribute to chemical resistance and, in some cases, enhanced oxygen barrier performance, such as in pharmaceutical blister packs. As a result, PFAS are present in a wider range of packaging materials and functional layers than might be immediately apparent.

Often referred to as “forever chemicals”, PFAS are persistent in the environment and can move throughout ecosystems, resulting in numerous pathways of exposure. Exposure to certain PFAS has been linked to a number of health risks, and some PFAS are associated with high global warming potentials. Governments have been taking steps to regulate PFAS use, with the goal of reducing human exposure and release into the environment.

PFAS under the PPWR

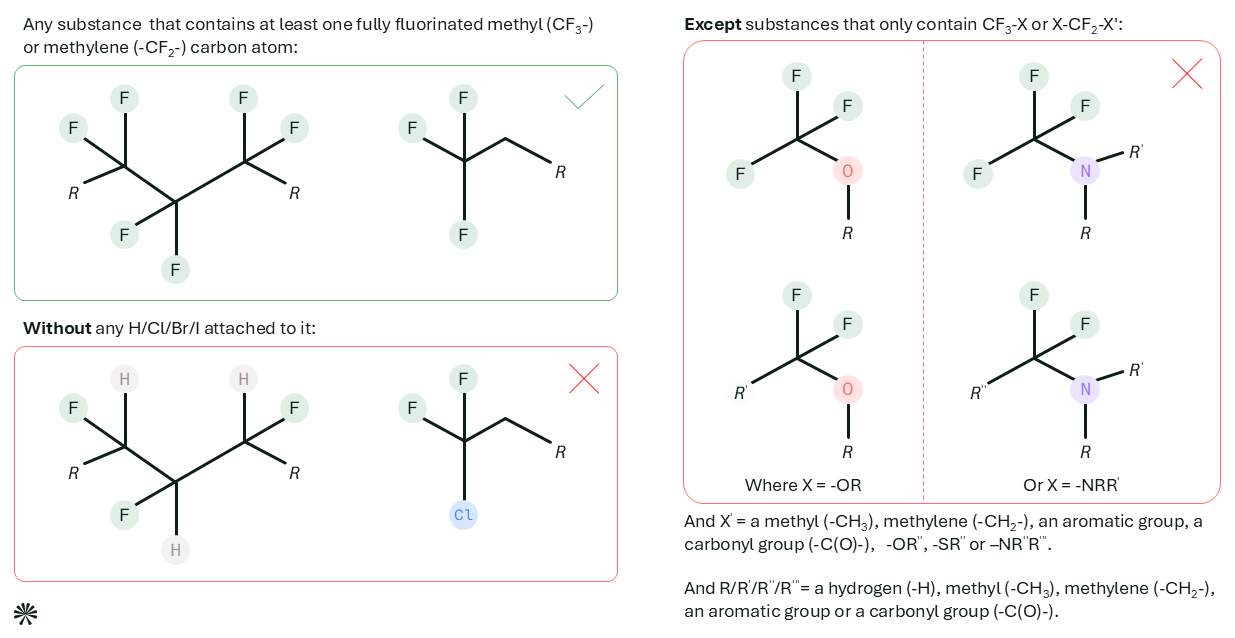

Different organisations use different definitions for PFAS. In the context of the PPWR a wide definition is used:

What PFAS requirements does the PPWR introduce?

Article 5 of the PPWR introduces a restriction on PFAS in food-contact packaging, effective 12 August 2026. In the context of the PPWR, food-contact packaging is packaging that is intended for food contact or that is already in contact with food. This includes disposable packaging for filling at point of sale, such as single-use cups used to serve takeaway beverages.

The PPWR sets three PFAS limits in food-contact packaging:

- Individual non-polymeric PFAS detected by targeted analysis: 25 ppb

- Total non-polymeric PFAS detected by targeted analysis: 250 ppb

- All PFAS, including polymeric PFAS: 50 ppm

Packaging manufacturers must provide technical documentation showing compliance with this restriction. If total fluorine exceeds 50 ppm, suppliers must, upon request, provide evidence indicating how much of that fluorine is from PFAS and how much from non-PFAS.

What future implications might PPWR developments have for PFAS in packaging?

In the coming years, some additional provisions under the PPWR may become relevant for the PFAS content of food-contact packaging, and/or other packaging.

Substances of concern

Article 5 of the PPWR stipulates that the Commission should consider measures to address substances of concern (SoCs), such as restrictions on their use. Producers and users of non-food packaging should be aware that some PFAS will be considered SoCs under the PPWR, and the use of these PFAS in non-food packaging may be restricted in the future.

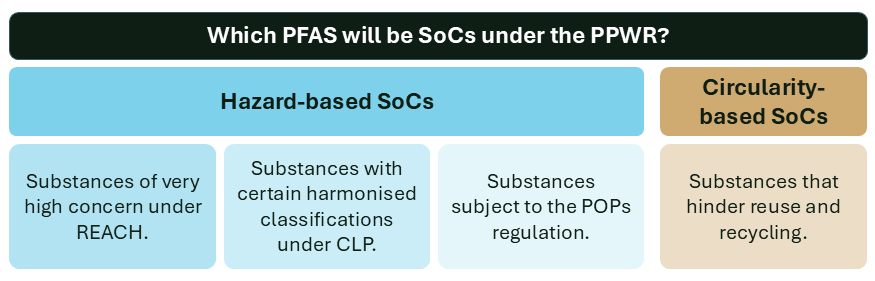

The PPWR uses the definition of SoCs from Article 2(27) of the Ecodesign for Sustainable Products Regulation (ESPR). Based on this definition the following PFAS are SoCs under the PPWR:

Recycled content

Article 7 of the PPWR sets targets for recycled content in plastic packaging. Recycled material can contain PFAS. As they work to increase recycled content, producers of food-contact packaging must remain compliant with the PPWR’s PFAS threshold, and producers of non-food packaging should be aware of any new SoC thresholds.

Digital marking

Article 12 of the PPWR provides for the use of digital marking technology to convey certain types of information. By 1 January 2030, this technology will be required to identify SoC content in packaging. Where the packaged product requires a digital product passport (DPP), for instance under the ESPR, this packaging data should be contained in the DPP.

What should you do now?

There are several steps companies can take to prepare for the PFAS requirements under the PPWR:

1. Identify PFAS hotspots

Companies should begin by reviewing their portfolio to identify likely PFAS hotspots. This can be done by scanning for characteristics and functions commonly associated with intentional PFAS use, such as grease- and moisture-resistance. The PPWR does not differentiate between intentionally added and non-intentionally added PFAS in determining compliance, so companies should also identify common sources of non-intentionally added PFAS, such as recycled paper and cardboard. Given the short timeline, hotspots can be prioritised in the next steps.

2. Collect PFAS data

Suppliers of packaging materials should check whether PFAS in their portfolio fall within the PPWR’s definition.

- If the total fluorine in their product is expected to exceed 50 ppm, they should perform total fluorine analysis. If total fluorine does exceed 50 ppm, they should determine the amount of total fluorine from PFAS and be prepared to provide this information to downstream users upon request.

- If non-intentional PFAS is likely, such as in recycled cardboard, suppliers should consider performing targeted analysis to verify if their products are compliant with the 25 and 250 ppb thresholds.

Users of packaging materials should reach out to their suppliers to ask if they know of any PFAS in their materials and if they perform targeted PFAS tests and/or total fluorine analyses.

3. Develop a Mitigation Strategy

Finally, companies should develop a strategy for mitigating their risk of PFAS exposure and for complying with the PPWR, including:

- Performing an alternatives assessment, with particular attention to ensuring that the alternatives do not hinder recyclability.

- Developing best practice guidance for transitioning to sustainable packaging.

How Anthesis can help

Anthesis can assist both suppliers and packaging manufacturers in reviewing their portfolios and advising on compliance with the PFAS requirements in the PPWR. Our digital solutions enable the collection and management of all relevant supply chain and portfolio data. We have extensive expertise in food contact materials, packaging, and chemicals regulations, including supporting our clients with:

- Tracking relevant PFAS regulations in sectors and geographies specific to their products and evaluating their likely impact on business.

- High-level PFAS hot-spotting of product portfolios to better target supplier engagement strategies.

- Detailed supplier engagement using our Anthesis Compliance Suite platform to assess product & packaging portfolio’s for the presence of PFAS.

- Assessing PFAS from a Life Cycle Assessment perspective.

- Identification and assessment of alternatives to PFAS.

- Summarising and responding to tactical questions on reporting.

We can also provide support with recent national measures, such as PFAS restrictions in France and Denmark and North American PFAS reporting obligations, as well as horizon scanning and preparedness for upcoming measures, such as the expected EU-level universal PFAS restriction.

Whether you’re seeking regulatory clarity, safer alternatives, or strategic planning, Anthesis is here to help you stay ahead of the evolving PFAS landscape.

Our Guide to PPWR

Find out how the PPWR impacts your business, and how to manage your response through strategic impact assessments and robust packaging strategies.

Explore our packaging services

Learn more about how we support sustainable packaging in design and production.

We are the world’s leading purpose driven, digitally enabled, science-based activator. And always welcome inquiries and partnerships to drive positive change together.