Home Solutions Sustainable Products and Circularity Packaging

Home Solutions Sustainable Products and Circularity Packaging

Our team of experts advise global organisations across the packaging value chain including retailers, manufacturers, brand owners, associations, and NGOs.

We support clients in navigating the balance of functional and economic needs of their packaging with the dynamic sustainability landscape. We build packaging footprints, craft data-led sustainable packaging goals, create holistic and transformational packaging strategies.

Clients’ projects can leverage our packaging engineers and subject matter experts to understand and go across the complexities of upstream and downstream supply chains in global markets. Our global resources can benchmark best practices, spot trends, evolving and fragmented legislation and help to identify and qualify meaningful sustainable packaging opportunities.

Developing a packaging footprint across a client’s packaging portfolio to support understanding of material and environmental impact. Mapping a packaging baseline to understand the client’s material footprint. This is a critical first step for identifying hotspots, establishing a sustainable packaging strategy, as well as for optimising for meeting EPR and broader disclosure requirements.

Building a tailored enterprise position and strategy to address internal ambition and external expectations. Supporting the development of goals and actionable glidepaths through research, analysis and gap to goal scenario modelling.

Researching global and local market relevant policies and legislation, conducting risk analysis and recommending strategies for risk mitigation. Interpreting recyclable definitions and recyclable content mandates. Assisting with management and reporting for Extended Producer Responsibility (EPR) fees, packaging taxes and labelling regulations.

Performing LCA analysis to support packaging environmental footprinting, ecodesign, data-based goals, sustainability communication and green claims. Supported by digital LCA tools to aid packaging engineers in holistic and data led decision making. Identifying innovative material and/or technology solutions, considering cost, feasibility and scalability.

Landscape review of existing and upcoming waste infrastructure developments that will support the collection, sorting and reprocessing of packaging waste.

Developing data-based, substantiated narrative, reporting and infographics to communicate the sustainability attributes of the packaging.

By combining our deep scientific and technical understanding of sustainability with brand design agency 1HQ’s global team of design specialists, we provide the market with an end-to-end service offering for sustainable packaging design.

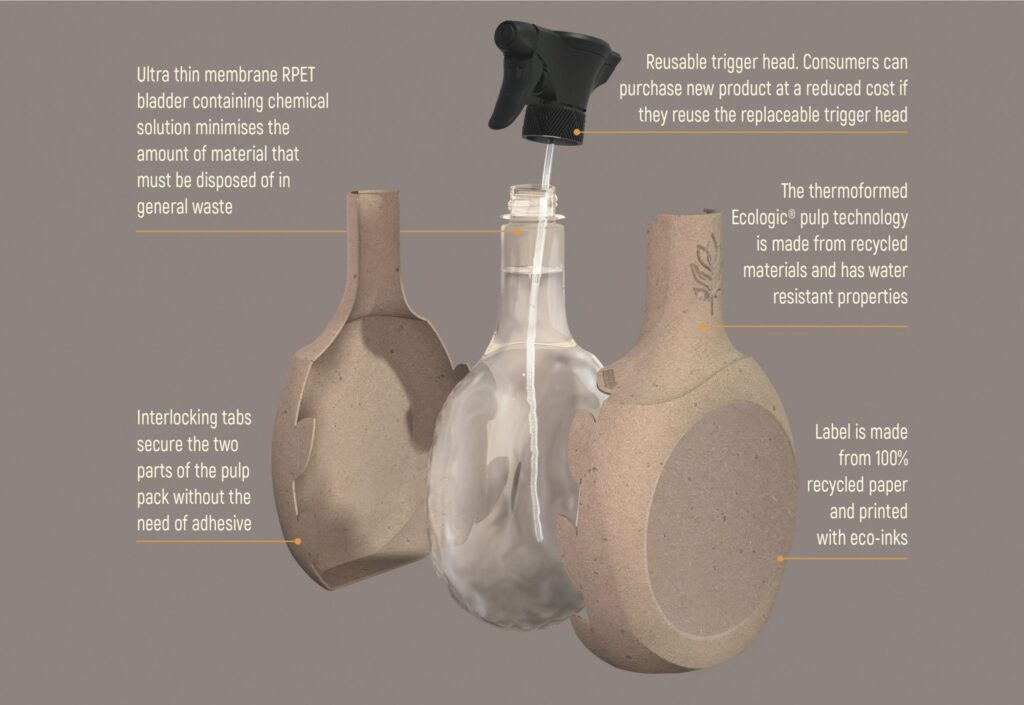

Completely new sustainable design solutions based on consumer usage journey:

Since 2014, we’ve been facilitating and supporting the Paper Cup Recycling and Recovery Group (PCRRG), a unique voluntary collaboration that brings together organisations from across the value chain, from manufacturers to retailers and the recycling sector – often seen as an industry best practice standard.

This group has delivered substantial change in the marketplace, through a series of ambitious programmes of work that collectively deliver on the group’s manifesto to increase recycling collections and infrastructure. In 2020, the group achieved its manifesto by obtaining OPRL labelling recognition thanks to the efforts of increasing recycling points available to consumers across the UK.

We are the world’s leading purpose driven, digitally enabled, science-based activator. And always welcome inquiries and partnerships to drive positive change together.